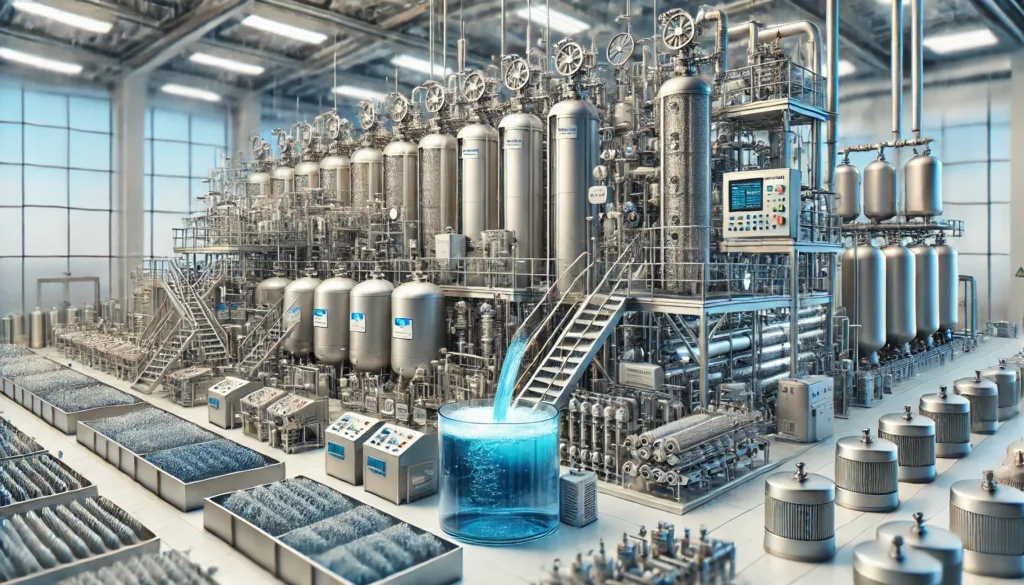

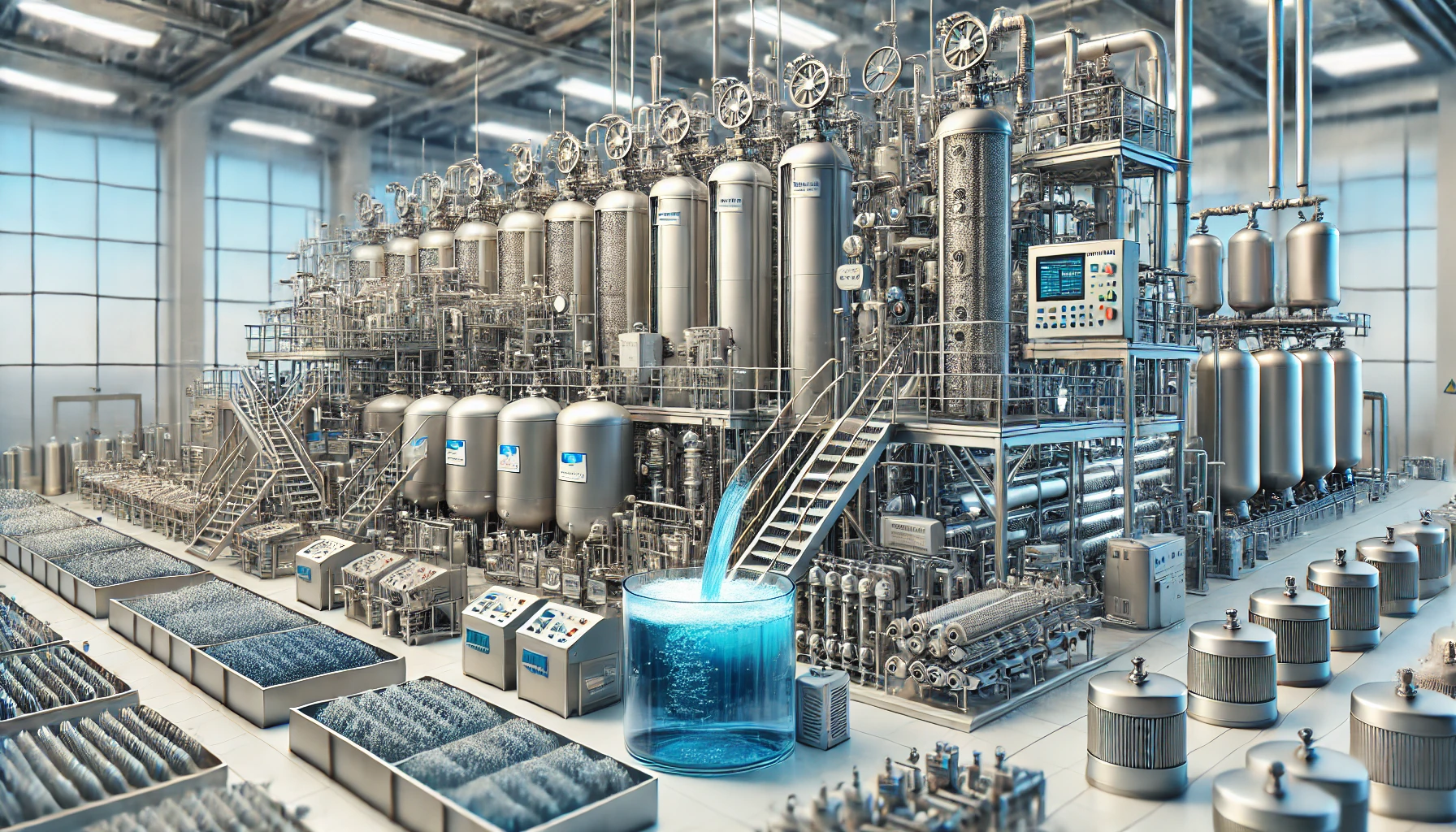

Ultrafiltration Water Treatment Plant I Lenntec, USA

An ultrafiltration (UF) water treatment plant is a facility that uses the ultrafiltration process to purify water. UF is a membrane filtration method that removes suspended particles, bacteria, viruses, and certain high-molecular-weight substances from water. It is commonly used for municipal drinking water, industrial water treatment, and wastewater recycling.

Key Aspects of an Ultrafiltration Water Treatment Plant:

- Ultrafiltration Membranes:

- Membrane Pore Size: The pores in UF membranes are typically between 0.01 to 0.1 micrometers, which is smaller than bacteria and viruses, allowing the membranes to filter out these contaminants.

- Materials: UF membranes are often made of materials such as polyethersulfone (PES) or polyvinylidene fluoride (PVDF), offering durability and chemical resistance.

- Process Overview:

- Pre-treatment: Inlet water may go through pre-treatment to remove larger particles or to adjust pH, which helps protect the UF membranes from damage or fouling.

- Feed Water: Water is pumped through the UF membranes. The filtration occurs under pressure, with contaminants being retained while purified water (permeate) passes through.

- Backwashing: To maintain efficiency, the UF membranes are periodically backwashed to clean them and prevent clogging. Chemicals may also be used to clean the membranes.

- Applications:

- Drinking Water Treatment: Removes pathogens, particulates, and turbidity, making it ideal for producing clean, potable water.

- Wastewater Treatment: UF is used to treat wastewater for reuse in industrial processes or irrigation, as it can effectively remove contaminants and reduce total suspended solids (TSS).

- Desalination Pre-treatment: Often used as a pre-treatment step in reverse osmosis (RO) systems to protect the RO membranes from fouling.

- Advantages:

- High Efficiency: Can remove up to 99.9% of bacteria and viruses.

- No Chemicals Required: UF does not require the addition of chemicals, unlike coagulation or flocculation processes.

- Compact Footprint: UF systems are more compact than traditional filtration systems.

- Challenges:

- Membrane Fouling: Regular maintenance is required to prevent fouling, which can lead to decreased performance or damage to the membranes.

- Energy Consumption: While UF is less energy-intensive than processes like reverse osmosis, it still requires energy to maintain the pressure needed for filtration.

Overall, ultrafiltration is a reliable and efficient technology for water treatment, particularly where high-quality water is required.

If you looking professional Ultrafiltration Water Treatment Plant Supplier, please contact us. Cell: 01771646625 (WhatsApp)

No Comments