BioChemical Technology Effluent Treatment Plant (ETP)

Greenify specializes in delivering proficient, cost-effective, and regulatory compli- ant wastewater treatment solutions, with its meticulously designed Effluent Treat- ment Plant (ETP). Throughout its more than era of existence, Greenify has consistently provided exemplary services & solutions, ensuring excellent performance in the Engineering, Procurement, and Commissioning of Biochemical ETP Plant Supplier.

Our EPT’s are designed with Quality and economy at its focus, without cutting corners. The ETPs are designed, procured and commissioned by our passionate and experienced team of specialists. Such Plants have been com- missioned nationally as well as internationally across various industries. Greenify configures ETP with advanced process design units with an objec- tive to provide flexibility of either disposal of treated water or reusability with Zero Liquid Discharge (ZLD) treatment.

Our services encompass design, engineering, supply, installation, commis- sioning as well as operation and maintenance of ETPs with conventional as well as ZLD technologies. We also work closely with the groups of industries to set up a CETP in industrial estates/Industrial clusters with all essential resources required for the establishment.

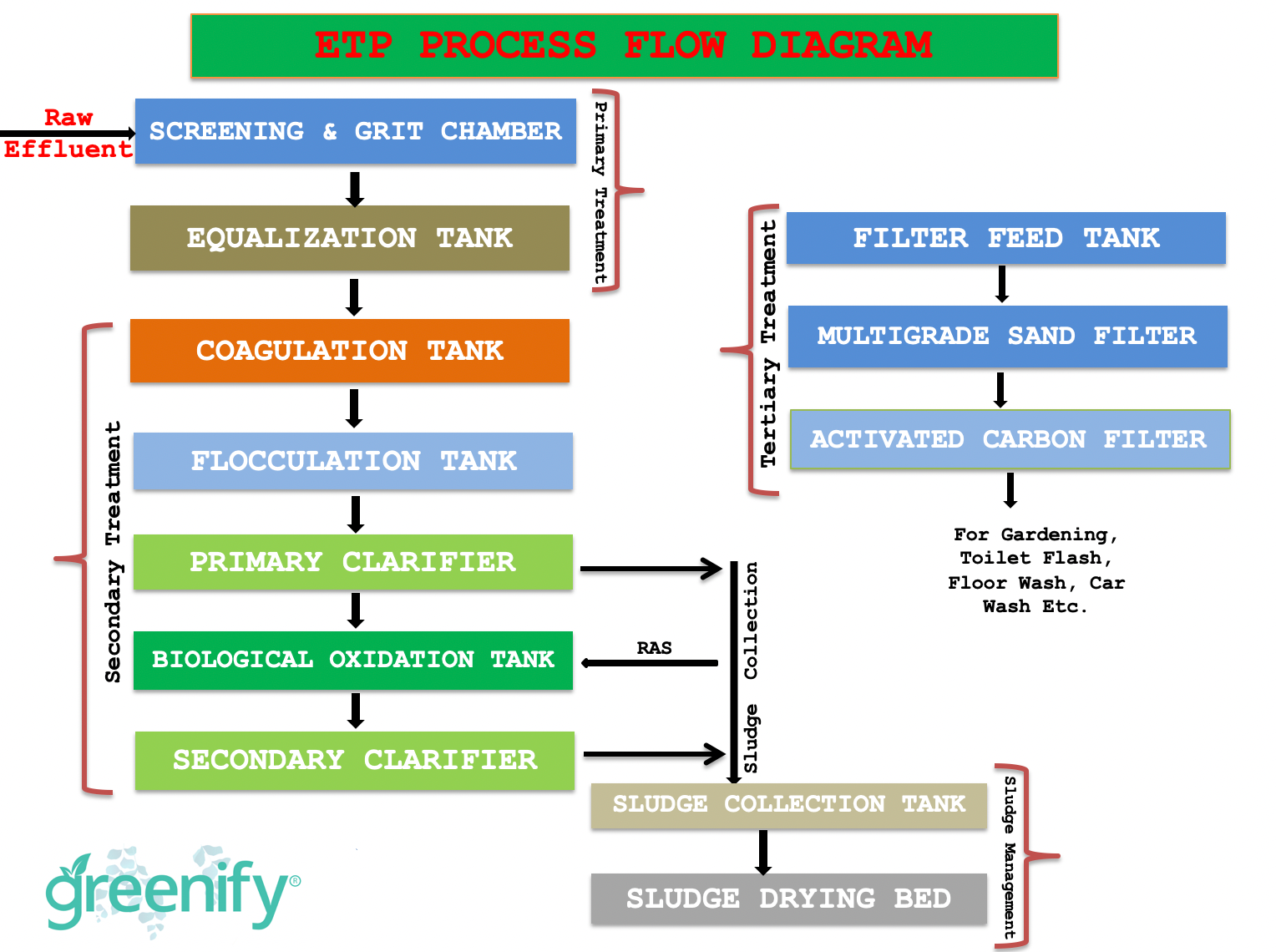

Process Flow Diagram of BioChemical ETP Plant:

Process Details of ETP Plant:

- Equalization Tank: Influent stream free from large physical contents & free from any kind of Oil-grease flows to main storage tank. The mass is kept in continuous movement by forced mixing, which is obtained by diffuser creating micro-bubble oxygen injection. In this phase also, a pre-oxidation stage of the wastewater is achieved. This tank allows for a homogeneous effluent to be transferred to secondary treatment system.

- Coagulation Tank: A rapid (or flash) mixer is used to uniformly disperse and blend chemicals, such as coagulant aids, chlorine, and sulfur dioxide, into the process stream. These chemicals, either in solution or slurry form, are added for the purpose of neutralization, odor & color control, and/or to aid in the removal of solids.

- Flocculation Tank: Flocculation is based on a chemical process. It involves adding chemicals to the wastewater in sequence and allowing tiny solid particles to collect together in a larger mass called a floc. As a treatment of wastewater, flocculation is carried out in stages.

- Primary Clarifier Tank: The clarifier works by permitting the heavier and larger particles to settle to the bottom of the clarifier. The particles then form a bottom layer of sludge requiring regular removal and disposal. Clarified water then proceeds through several more steps before being sent for storage and use.

- Biological Oxidation Tank: The tank to manage the desired bio-degradation and conversion into activated Bio-sludge to separate undesired available organic contamination. Biological Oxidation is carried out through the action imparted by bacteria and aerobic micro-organism on the polluting load. This tank acts as a polishing tank and makes the sludge settleable to be clarified in clarifier. The necessary oxygen is supplied by blowers and diffusers are used for proper aeration.

- Secondary Clarifier Tank: To ensure the fast & efficient separation of flocs, conical bottom tank is required. Bio-decomposed effluent gets separated into two streams as clear water over-flows from the top of clarifier & sludge from the conical bottom.

- Filtration Unit: Using filtration in water treatment, solid particles are entirely removed from the water. This can be from ground water, surface water or even pre-treated wastewater. These processes in water treatment have a clear objective: to provide the correct quality of water for the specific industrial application.

- Discharge Pit: After Filtration process, treated water goes to the discharge pit where treated water going to main drain line.

If you’re looking BioChemical ETP Plant Supplier in Bangladesh, Please contact with us. Call: 01771646625 (WhatsApp)

We have well experience engineer to meet your BioChemical ETP Plant demand.

No Comments