Description

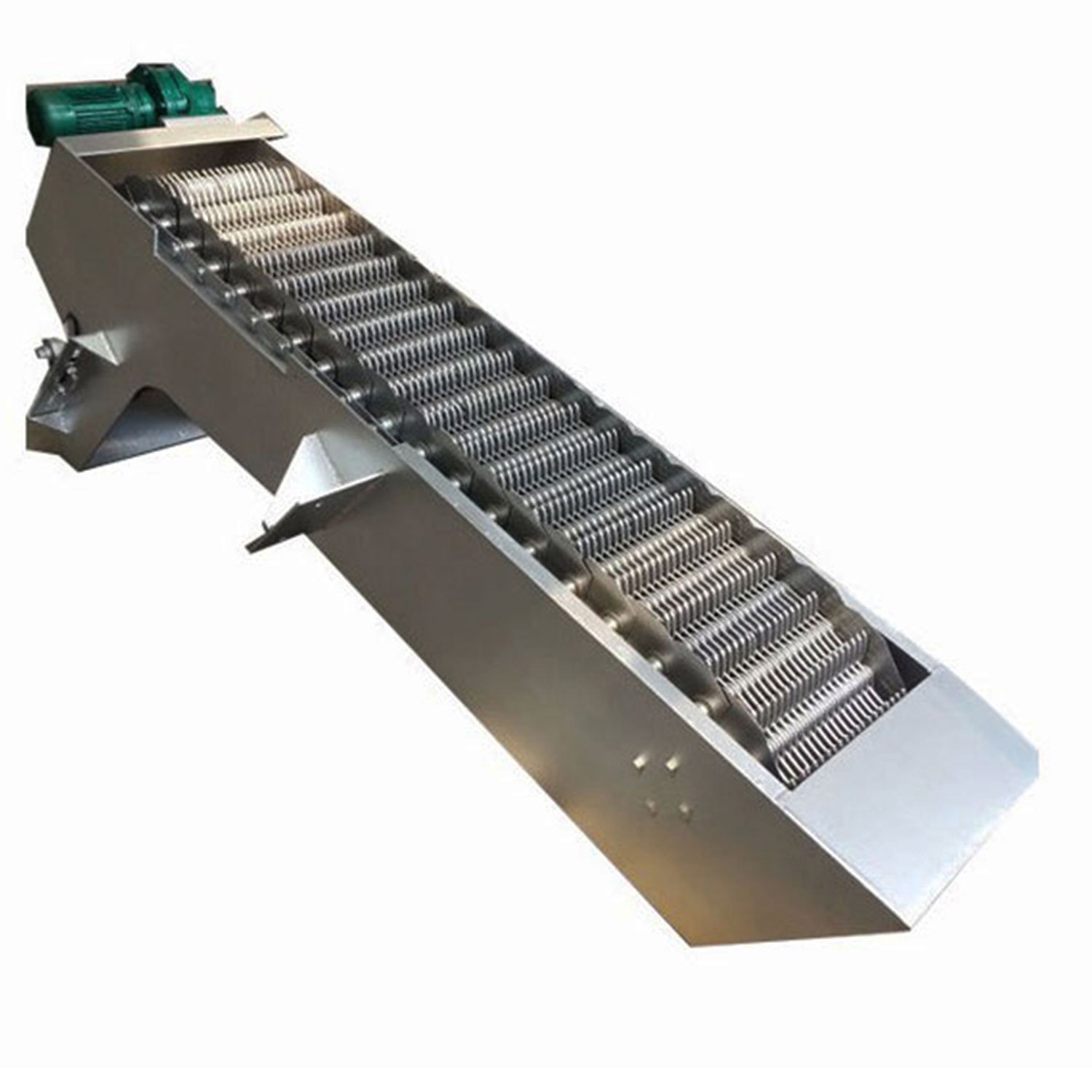

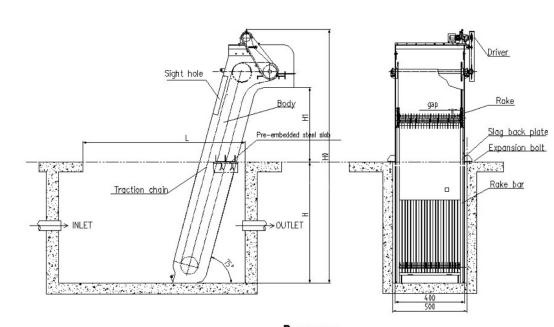

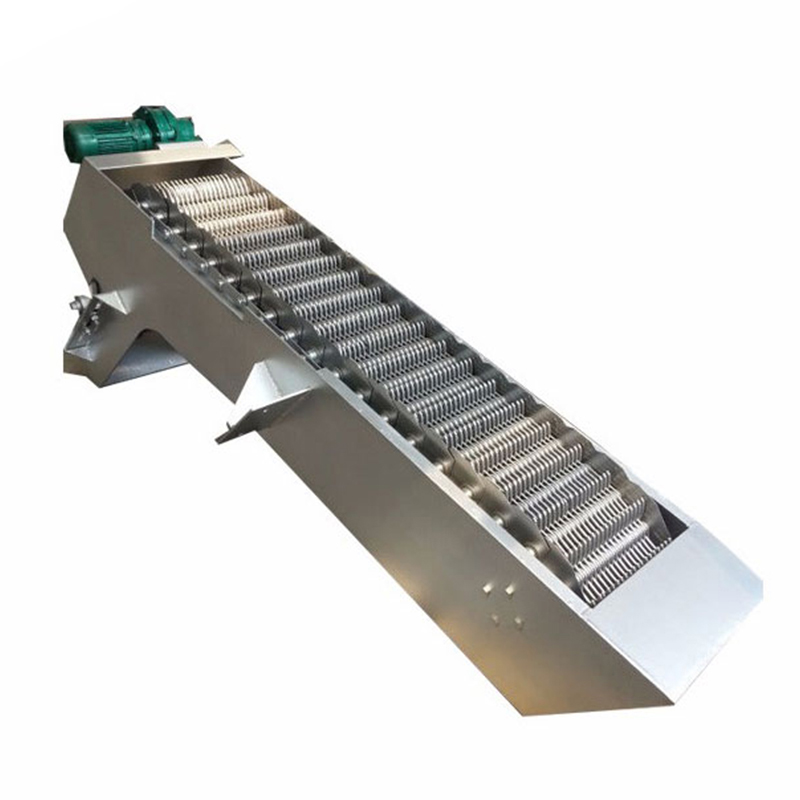

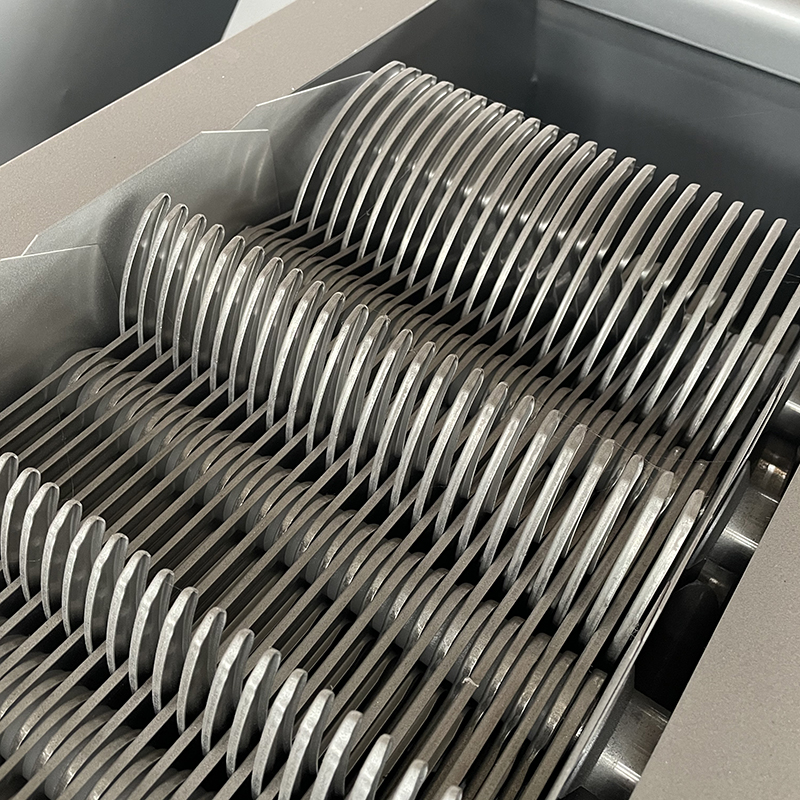

A Mechanical Bar Screen is an advanced device designed for effective solid-liquid separation in water treatment systems. It is equipped with several special-shaped teeth that are strategically assembled onto a teeth axis, forming a sealed teeth chain. This innovative design ensures efficient filtration by allowing the rake chain to move smoothly when the chain wheel rotates in a specific direction at a consistent speed. The lower part of the bar screen is installed at the water inlet, where the attached solid debris is separated from the liquid, allowing the fluid to flow through the gaps.

As the rake chain reaches its upper end, each group of rakes undergoes self-cleaning, with the solid material dropping out under the influence of gravity and the guiding rail. Any remaining solids are cleaned by a back-running brush. This entire process occurs continuously and automatically, making the Mechanical Bar Screen an essential component in solid-liquid separation, ensuring both efficiency and reliability in water treatment operations.

Technical Parameters:

| Model /Parameter | GETL-500 | GETL-600 | GETL-700 | GETL-800 | GETL-900 | GETL-1000 | GETL-1100 | GETL-1200 | GETL-1300 | GETL-1400 | GETL-1500 | ||

| Device Width B(mm) | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1300 | 1400 | 1500 | ||

| Channel Width B1(mm) | B+100 | ||||||||||||

| Effective Grille Spacing B2(mm) | B-157 | ||||||||||||

| Anchor Bolts Spacing B3(mm) | B+200 | ||||||||||||

| Total Width B4(mm) | B+350 | ||||||||||||

| Teeth Spacing b(mm) | t=100 | 1≤b≤10 | |||||||||||

| t=150 | 10<b≤50 | ||||||||||||

| Installing Angle α(°) | 60-85 | ||||||||||||

| Channel Depth H(mm) | 800-12000 | ||||||||||||

| Height Between Discharge Port and Platform H1(mm) | 600-1200 | ||||||||||||

| Total Height H2(mm) | H+H1+1500 | ||||||||||||

| Back Rack Height H3(mm) | t=100 | ≈1000 | |||||||||||

| t=150 | ≈1100 | ||||||||||||

| Screen Speed v(m/min) | ≈2.1 | ||||||||||||

| Motor Power N(kw) | 0.55-1.1 | 0.75-1.5 | 1.1-2.2 | 1.5-3.0 | |||||||||

| Head Loss(mm) | ≤20(no jam) | ||||||||||||

| Civil Load | P1(KN) | 20 | 25 | ||||||||||

| P2(KN) | 8 | 10 | |||||||||||

| △P(KN) | 1.5 | 2 | |||||||||||

Note:Pis calculated by H=5.0m,for every 1m H increased,then P total=P1(P2)+△P

t:rake tooth pitch coarse: t=150mm

fine: t=100mm

| Model /Parameter | GETL-500 | GETL-600 | GETL-700 | GETL-800 | GETL-900 | GETL-1000 | GETL-1100 | GETL-1200 | GETL-1300 | GETL-1400 | GETL-1500 | ||

| Flow Depth H3(m) | 1.0 | ||||||||||||

| Flow Velocity V³(m/s) | 0.8 | ||||||||||||

| Grid Spacing b(mm) | 1 | Flow Rate Q(m³/s) | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.08 | 0.09 | 0.10 | 0.11 | 0.12 |

| 3 | 0.07 | 0.09 | 0.10 | 0.12 | 0.14 | 0.16 | 0.18 | 0.20 | 0.22 | 0.24 | 0.26 | ||

| 5 | 0.09 | 0.11 | 0.14 | 0.16 | 0.18 | 0.21 | 0.23 | 0.26 | 0.28 | 0.31 | 0.33 | ||

| 10 | 0.11 | 0.14 | 0.17 | 0.21 | 0.24 | 0.27 | 0.30 | 0.33 | 0.37 | 0.40 | 0.43 | ||

| 15 | 0.13 | 0.16 | 0.20 | 0.24 | 0.27 | 0.31 | 0.34 | 0.38 | 0.42 | 0.45 | 0.49 | ||

| 20 | 0.14 | 0.17 | 0.21 | 0.25 | 0.29 | 0.33 | 0.37 | 0.41 | 0.45 | 0.49 | 0.53 | ||

| 25 | 0.14 | 0.18 | 0.22 | 0.27 | 0.31 | 0.35 | 0.39 | 0.43 | 0.47 | 0.51 | 0.55 | ||

| 30 | 0.15 | 0.19 | 0.23 | 0.27 | 0.32 | 0.36 | 0.40 | 0.45 | 0.49 | 0.53 | 0.57 | ||

| 40 | 0.15 | 0.20 | 0.24 | 0.29 | 0.33 | 0.38 | 0.42 | 0.46 | 0.51 | 0.55 | 0.60 | ||

| 50 | 0.16 | 0.2 | 0.25 | 0.29 | 0.34 | 0.39 | 0.43 | 0.48 | 0.52 | 0.57 | 0.61 | ||

Contact

For the best price and further inquiries, feel free to contact us anytime.

Call: 01771646625 (available on WhatsApp) for quick assistance and more details about our products and services.