Description

MYDL131 Multi-disc Sludge Dewatering Screw Press machine belongs to the screw press; it’s clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction. MYDL uses screws and moving rings to clean itself as a clog-free structure and is controlled by the PLC automatically, it’s a new technology that can replace the traditional filter press like belt press and frame press, and the screw speed is very low, so it cost low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.

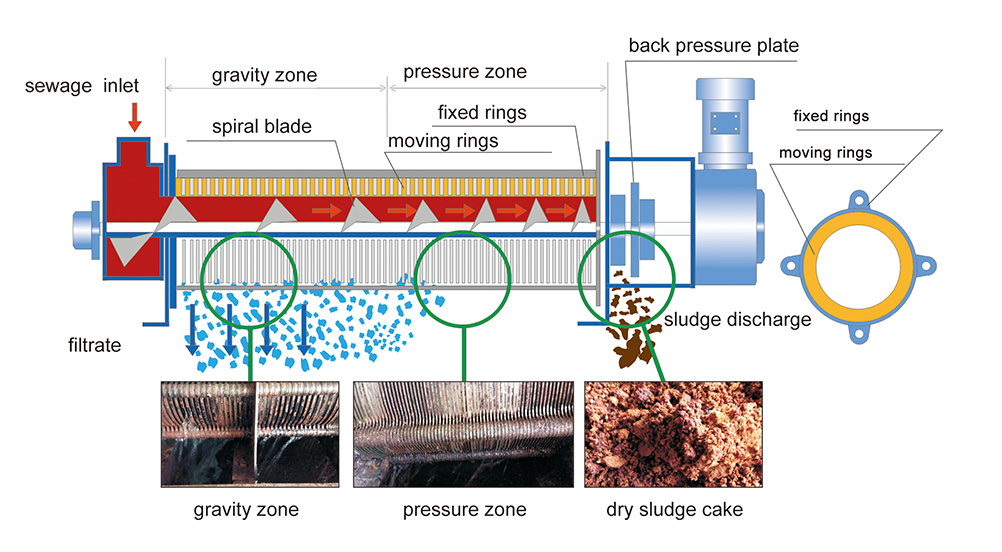

Working Principal of MYDL131 Screw Press Machine:

The conditioned sludge flows into the filter zones from the flocculation tank and is pushed forward to the discharging end. With the gaps between the shaft thread getting even narrower, the pressure on the sludge is getting higher and higher. Then, the water is separated from the sludge and flows out from the gaps between the moving and fixed rings. The movement of the moving rings will clean the gaps between moving and fixed rings and prevent the machine from blockage.

The filtered sludge cakes will be pushed forward by the finally discharged from the end.

Features:

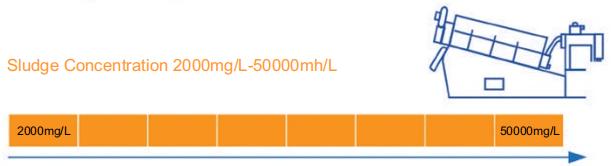

Configuring an exclusive spiral plate for pre-concentration is better for treating low-concentration sludge.

Replacing gravity-type dehydrator to realize efficient concentration of sludge.

Flocculation and concentration operating together make dewatering easy.

Optimize the concentration of slurry for dewatering with a solenoid control valve.

1. Rings substitute filter cloth, self-cleaning, no clogging, easy treatment.

The dewatering screw press allows continuous operation with no clogging due to the moving of the fixed rings and moving rings cleaning itself. Therefore, it’s especially good at oily sludge and performs excellently. Moreover, it doesn’t need additional water for high-pressure cleaning, so no tiny or secondary pollution will be produced.

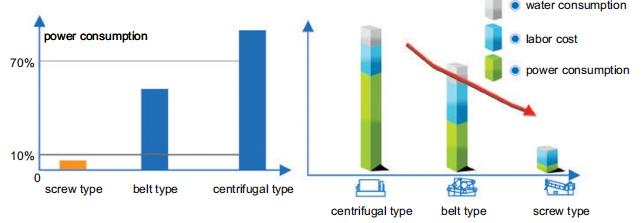

2. Low-speed operation, low noise, low energy consumption, only 1/8 of the belt type, 1/20 of the centrifuge.

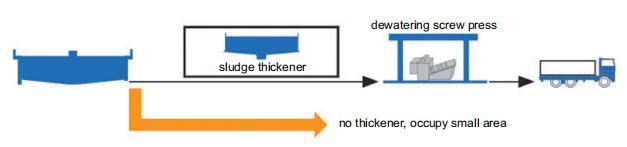

3. Reduce the cost of infrastructure investment, improve the result of treatment

The dewatering screw press can directly treat the sludge from the aeration tank and the sedimentation tank

so that the sludge thickening tank is not needed anymore.

Therefore, the construction cost can be significantly reduced and will avoid the phosphorus-releasing problem.

Saving the cost of sludge thickening tanks and other equipment investments.

Occupy smaller areas and reduce construction investment for dewatering.

4. Fully automatic control, easy operation and maintenance.

The dewatering screw press has no easy-blocking components like filter cloth or filtration pore inside.

Its operation is safe and easy. It also can be set to operate automatically via the elec-control cabinet.

Technical Specifications for all Models:

Model: MYDL131

DS capacity: 10~14 kg/h

Screw Specification: 130*1

Motor Power (kW): 0.36

Screw Shaft: 0.18kw

Mixer: 0.18kW

Voltage: 380V, 50Hz, 3Phase

Main material: SUS304

Clean Water Qty: 48L

Net Weight: 250kg

Operating Weight: 395kg

Brand: Techange

Origin: China

Control cabinet: LCP, European brands components, coated steel Cabinet.

Greenify is MYDL131 Screw Press Machine Supplier in Bangladesh. Contact us for a special price. Call: 01771646625 (WhatsApp)