Description

A Sludge scraper machine, frequently utilized in wastewater treatment plants, is a critical part for the expulsion of slime that settles at the lower part of clarifiers or sedimentation tanks. These machines are intended to constantly or discontinuously eliminate the ooze, which is a side-effect of the sedimentation cycle, to keep up with the productivity of the treatment framework.

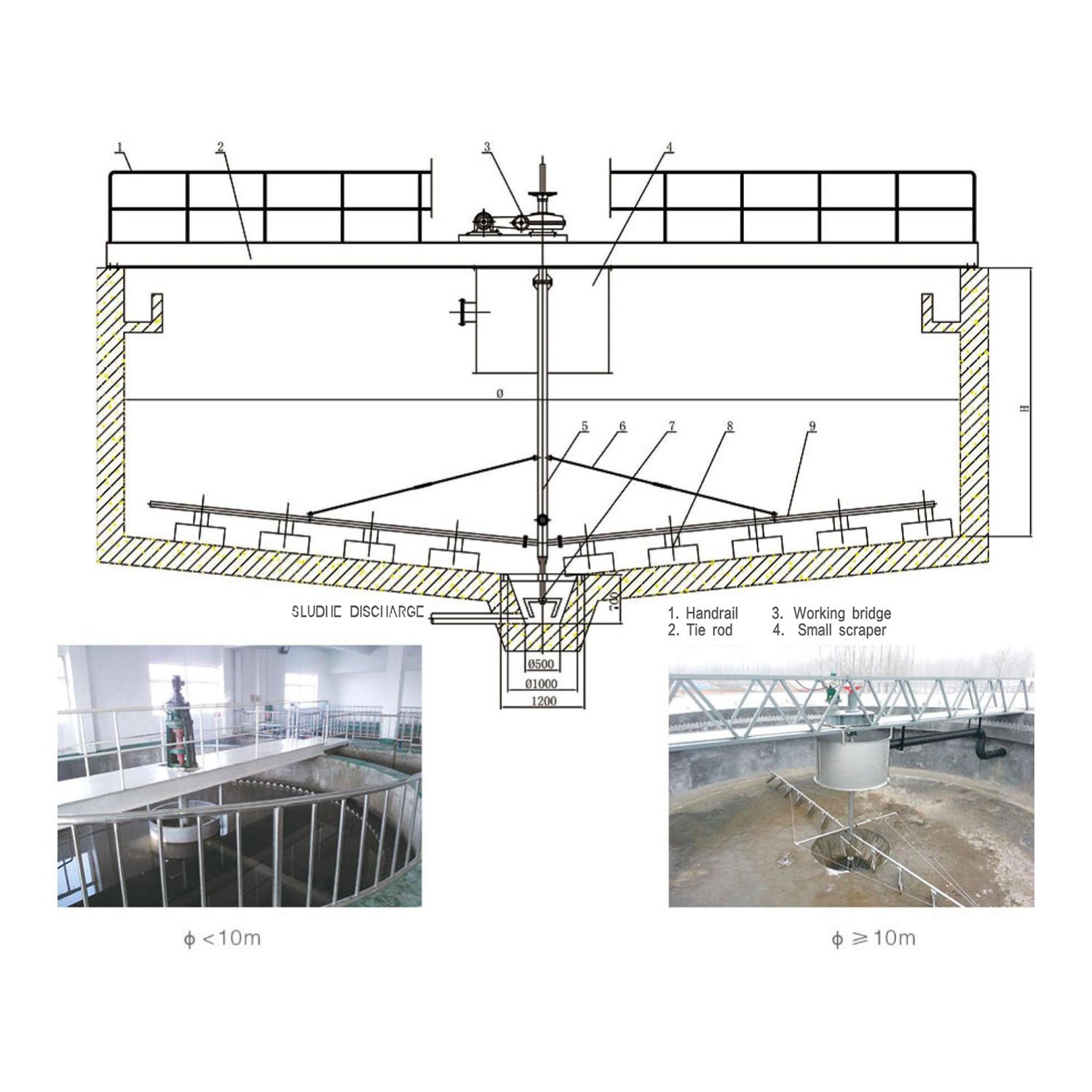

Key Components and Features of Sludge Scraper Machines:

Bridge/Truss Structure:

Most sludge scrapers comprise a scaffold or bracket that traverses the width or length of the sedimentation tank. It fills in as the help structure for the scratching component.

Scraper Arms/Blades:

The primary component that moves along the lower part of the tank to gather ooze. The sharp edges push the settled muck towards an assortment point, typically an ooze container or siphon.

Drive Mechanism:

Engines and pinion wheels fuel the scrubber machine, permitting the scrubber to move gradually across the tank. The speed is generally movable in light of the muck-gathering rate.

Suction or Pumping System (in some models):

A few high-level frameworks use pull gadgets rather than mechanical scratching to gather slime all the more proficiently, particularly in tanks with fragile or lightweight slop.

Control System:

Current slime scrubbers have computerized control frameworks that screen muck levels, scrubber speed, and the machine’s general exhibition, guaranteeing ideal activity.

Types of Sludge Scrapers:

Peripheral Drive Scrapers: These have a mechanized arm that pivots around the fringe of roundabout clarifiers, scratching ooze towards the focal point of the tank.

Central Drive Scrapers: These are utilized for more modest tanks and include a scrubber arm that moves in a straight movement, gathering muck from rectangular or square tanks.

Chain and Flight Scrapers: Ideal for rectangular sedimentation tanks, where a progression of chains with flights (scratching bars) are utilized to drag slime towards an assortment point.

Materials:

Generally built from erosion-safe materials like hardened steel or covered metals to endure the cruel circumstances in wastewater conditions.

Energy Efficiency:

Many plans focus on low power utilization, utilizing gravity and sluggish systems to decrease energy use while maintaining high productivity.

Applications of Sludge Scraper:

- Wastewater Treatment Plants: To remove primary and secondary sludge.

- Industrial Wastewater Systems: To handle sludge from chemical, food processing, or other industrial processes.

- Clarifiers and Thickeners: Used in sedimentation tanks to ensure continuous removal of settled solids.

Contact

Contact us if you’re looking for a sludge scraper machine supplier in Bangalore. For special price contact us. Call: 01771646625 (WhatsApp)